2018

Plastic Pallet Machine: Plastic Pallets Cut Costs and Breakages

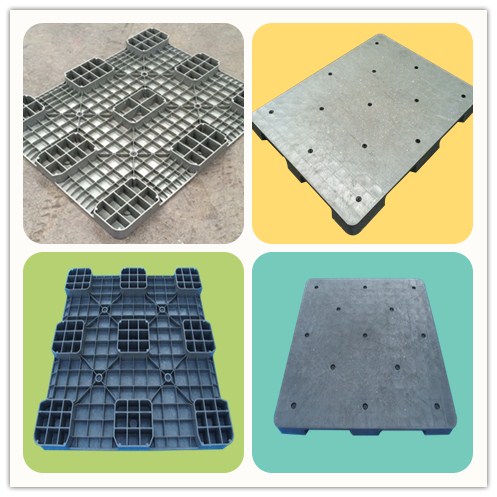

Plastic pallet machine is designed to produce various plastic moulding pallet. And PalletMach is the leading manufacturer of plastic pallet machine in China. Besides, our main item is plastic pallet moulding machine. In addition, PalletMach can supply the whole solution for plastic pallet production.

The logistics industry is busier than ever and with that comes the need for faster, more consistent distribution. Moulded plastic pallets have proved that they are more than capable for the job. But now we are seeing advances in the way that plastic pallets are made, which is opening doors to further possibilities.

Until a few years ago, the company used wooden pallets to transport their 50L kegs around the Netherlands. After suffering recurrent setbacks, such as the wood breaking during automation causing a halt to the production line, they decided enough was enough.

This company wanted to both eliminate the problems that were physically occurring with the wooden pallets, plus make the process safer whilst reducing their overall costs, so they contacted one of durable plastic pallets manufacturer. The solution proposed was to create a customized plastic pallet that featured centre rings to keep the kegs in position.

PalletMach plastic pallet machine produces good mouled plastic pallets with low price. Created specifically to work universally as logistics pallet, it is the ideal solution for crates, cans and glass bottles. Designed and manufactured by plastic pallet manufacturer, the company states that major achievements from this pallet include “lower breakage rates at less than one percent per trip” and “significant reductions in the monthly rental fee”.

Overall costs of using moulded plastic pallets designed specifically for the logistic industry are greatly reduced in comparison to that of a standard wooden pallet for many reasons, such as their long working life, reduction in breakages and efficiency in the job they are designed for.

Presentation is key when your brand is delivering so by having clean, built for purpose pressed plastic pallets you are portraying the message that you care about the quality of your products to your customers.

At PalletMach we have sold a lot of plastic pallet machines in the last 15 years, which help the clients to build their own pressed pallet. We are the protecter of plastic waste, which turning plastic wastes are recycled in a sustainable way to produce moulded plastic pallets.

Our advantages of plastic pallet machine

-

Advanced technology

PalletMach updates the traditional pallet making machine and independently produce the plastic pallet moulding machine. This production line adopts new technology to reduce the cost of raw materials. PLC system controls the whole production process of pressed plastic pallets. And the production dates also can record and recall at any time.

-

Low production cost

The price of the raw materials is less than 50%, so the production cost is also lower than 50%. In addition, the technology process of plastic pallet making line is easier, and easy to operate.

Raw materials for plastic pallet machine are, PVC, PP, PS, HIPS, PET, APET, PETG, waste plastic, HDPE scrap, PE scrap, PP scrap, PVC wire skin, waste plastic pallet, and so on.

-

Environmental protection

Plastic pallet machine is the ideal machine to recycle waste plastic. And plastic pallet making machine is changing the waste plastic into new plastic pallets, so it helps to protect the environment.

-

Good final pallet

The quality of final plastic pallets is as good as the traditional injection moulding plastic pallets. Meanwhile, the final pallets are one-piece design, which are saving space 60% than the traditional ones.

If you want to get more information, please contact us via email [email protected].

Leave a Message